Electronic cables for use in drag chains

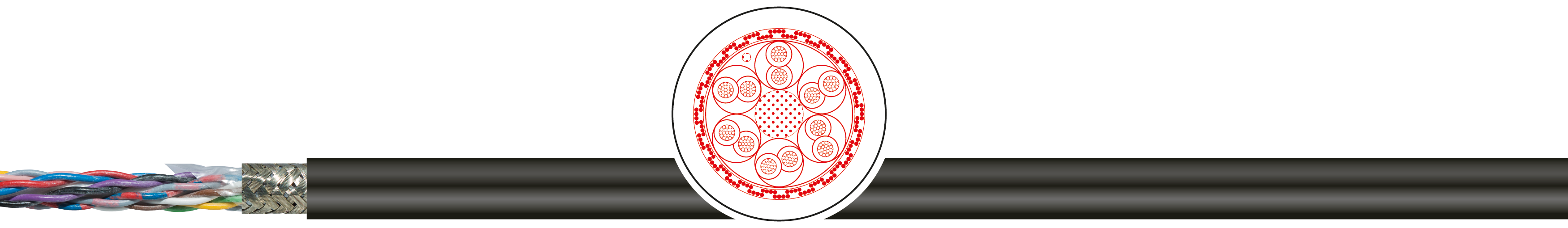

KAWEFLEX® Allround 7720 SK-TP-C-PUR UL/CSA

04.15.10

|

Use of Cable

twisted pair shielded electronic cable for data and signal transmission for high requirements in drag chains, in electrical motion facilities, machine and plant engineering in the field of crane and conveyor facilities in dry and humid rooms also outdoor.

Product information "KAWEFLEX® Allround 7720 SK-TP-C-PUR UL/CSA"

Special features

- UL/CSA approved

- resistant to oil acc. to DIN EN 60811-404, 168 h at +100 °C

- flame-retardant and halogen-free

- UV and weather resistant

- silicone-free

- recommended for EMC-application

- NEW: with Rip Cord, for faster and core protected dismantling

- conform to RoHS

- conform to 2014/35/EU-Guideline ("Low-Voltage Directive") CE

- very long lifetime, optimal cost-value ratio

| Conductor material: | Bare copper strand |

|---|---|

| Conductor class: | Acc. to DIN VDE 0295 cl. 6 resp. IEC 60228 cl. 6 |

| Core insulation: | PELON®2 |

| Core identification: | Acc. to DIN 47100 |

| Overall stranding: | Pairs stranded around tensile strength center, opt. lay length |

| Inner sheath material: | PUR, with Rip Cord |

| Shield3: | Copper braid tinned, opt. coverage min. 85% |

| Outer sheath: | PUR |

| Sheath colour: | Black, RAL 9005 |

| Rated voltage: | 300/300 V |

| Testing voltage: | 1.500 V |

| Conductor resistance: | At +20 °C acc. to DIN VDE 0295 cl. 6/IEC 60228 cl. 6 |

| Min. bending radius fixed: | 5 x d |

| Min. bending radius moved: | 10 x d |

| Operat. temp. fixed min/max: | -40 °C / +80 °C |

| Operat. temp. moved min/max: | -25 °C / +80 °C |

| Burning behavior: | Acc. to IEC 60332-1, cable flame test, FT1 |

| Approvals: | UL/CSA - cURus 80 °C, 300 V |

| Speed: | Self-supporting: max. 10 m/s, gliding: max. 5 m/s |

| Acceleration: | Max. 80 m/s² |

| Bending cycles: | Up to 10 Mio. |

There aren't any asked questions yet.

KAWEFLEX® Allround 7710 SK-TP-C-PVC UL/CSA

04.15.05

Electronic cables for use in drag chains

for increased requirements, 300V, shielded, UL/CSA

for increased requirements, 300V, shielded, UL/CSA

Item count

24

KAWEFLEX® Allround 7730 SK-TP-C-TPE UL/CSA

04.15.15

Electronic cables for use in drag chains

for highest requirements, 300V, shielded, UL/CSA

for highest requirements, 300V, shielded, UL/CSA

Item count

26

KAWEFLEX® Allround 7720 SK-TP-C-PUR UL/CSA

04.15.10

Electronic cables for use in drag chains

for high requirements, 300V, shielded, halogen-free, UL/CSA

for high requirements, 300V, shielded, halogen-free, UL/CSA

Item count

24